Contributed by George King

The notes & photos below document the personal experiences of George King working on the early startup segments of the BMEWS Project.

For the Thule, Greenland base, I was assigned as Project Engineer on four antennas and four scanner buildings in the very early phase of the project to make sure all the pieces of the project held together. Also, I was assigned as weather man. I put up a standard USA type wind speed intrument which blew down in a phase 3, 120 mpg wind. This was changed to an airplane type pitot tube which worked well measuring at least 160 mph wind. The weather station was critical with 200 contractor personnel working at J-Site. I called my father, Gogebic County Road Superintendent in Northern Michigan for research on wind driven snow drifts that are a calculated distance behind a snow fence.

A large crew of radar engineers were assigned to the three transmitter and four scanner buildings and radar electronics both in Greenland and a similar set of two transmitter and three scanners at Clear, Alaska 20 air miles southwest of Fairbanks.

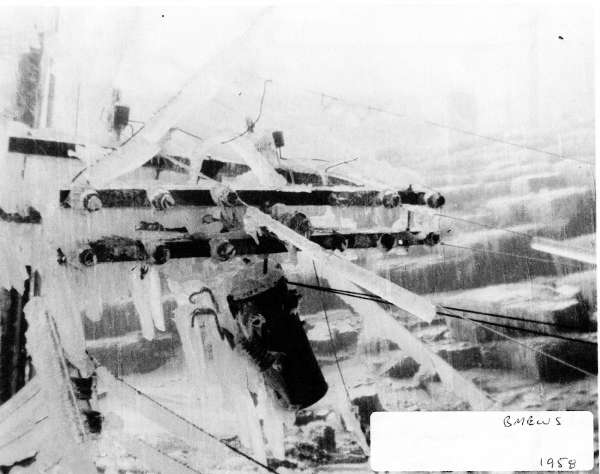

The ice storm picture was of an early event we had to contend with. The power lines from the military power ship at Thule AFB had to be rebuilt after a one day ice storm off the ice cap two miles away.

With a site selection group and two RCA construction engineers, we were in a quanset hut meeting on J Site with about ten from the contractors group. Nothing around except ice and our entertainment of about a dozen white arctic fox that quickly showed up from some place scrounging for our lunch scraps. We polled the personnel at the meeting and found that all the guys were selected from norther USA, Minnesota, Utah, New York, Wisconsin, Michigan and Montana, with cold climate experience.

1958-59 - Trial installation of the antennas: During the summer, the contractors erected more building and 25 ton concrete antenna foundations. Under pressure to complete the job on schedule, they jumped the gun with a trial installation of the first antenna section. About complete, 120 feet high and 400 feet long, some heavy bolts broke, went bang, and fell to the ground, a serious personnel hazard. Our shop mounted one of the broken bolts on a wood base, and it was presented to me as a reminder of the whole episode.

Part way up, an antenna section started fall apart due to cold temperature cycling. A real personnel hazard and panic. The antenna construction project was stopped to determine the problem. Some broken steel parts were flown back to Moorestown, NJ via a C-118 cargo plane for analysis by Dick Dunphy, staff RCS metallurgiste, who said "you have a brittle fracture, wrong material. The broken bolts are ordinary carbon material, not specification, all weather chrome steel 1 1/2%."

Big problem! A steel yard on site was mixed with a wrong material. Several wind storms off the ice cap buried everyting in the steel yard to 25 feet.

George King standing on top of an ice drift on top of a pile of steel.

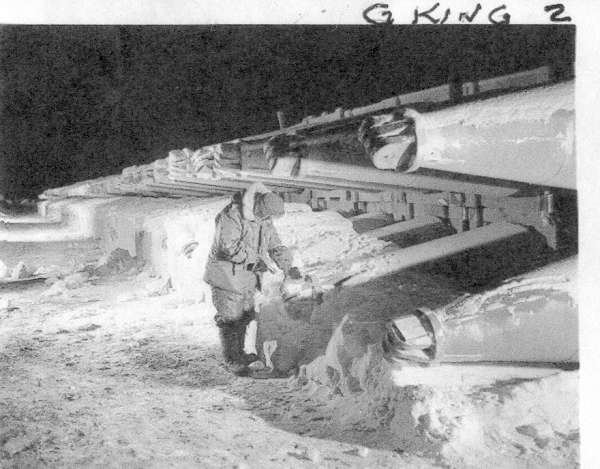

King inspecting the steel yard after the contractors dug out the material in two days with several backhoes and plows that had to run 24 hours a day to avoid freeze up.

Ready for inspection to identify every piece of the "erector set" of several hundred heavy metal parts including 1/8" wall pipe all flown in and stored in the steel yard.

With a crew of eight GE engineers flown in for the purpose, every part was checked and sorted (using the classical dissimilar metal method done electrically with special instrumentation for the purpose).

Flash back: My boss asked me to check on the quality of the antenna manufacturing in progress at a subcontractor of GE in Massachusetts. A GE engineer and I went in after hours late one day and found a very poor welding technique. Quality control was not evident. My trip report passed around to my management was "hot". Nobody would touch it. I was a "whistle blower" identifying problems that could seriously delay delivery of the material to Greenland which had to make the Thule port on three ships ahead of a September freeze up. A management decision was made to go ahead.

Delivery was made to Thule ahead of the port freeze. Turns out that the steel fabricator, a subcontractor, was working 24 hours a day, was under very heavy pressure to complete the job on time.

The project required a specification chrome steel to survive cold weather and was in short supply. Ordinary carbon steel was substitured without documentation and got mixed in with the whole delivery. The problem showed up on site when the partially erected antenna started to fall apart with the cold temperature cycling typical near the ice cap. An eight-man crew flown in for the purpose sorted the antenna parts using the well known dissimilar metal technique measureing every part.

All the sorted steel from the steel yard was flown back in C-118 cargo planes and remanufactured - many trips and a high cost charged to the Air Force. GE covered the $1.5 million expense with their insurance. With all this the delivery schedule was met.

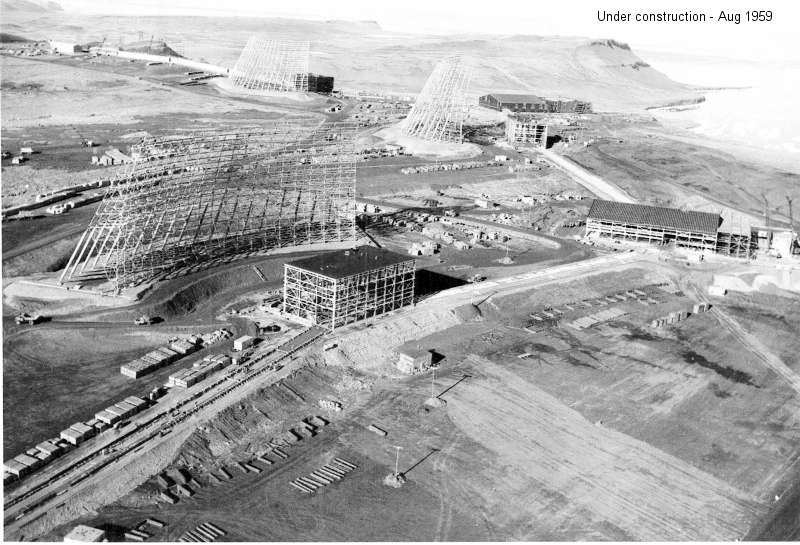

August 8, 1959: Aerial view of buildings partly constructed and four antennas show. Also truck sized tunnels partly done connecting all of the buildings.

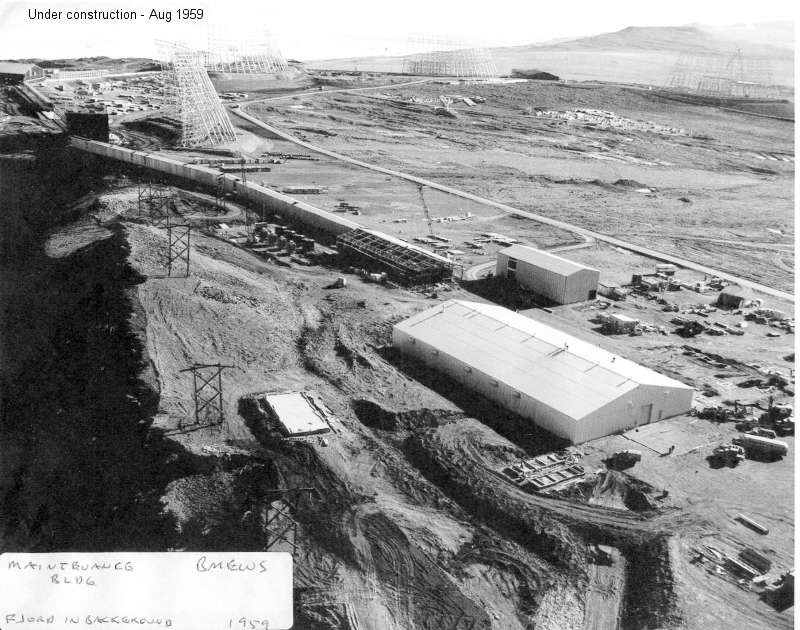

August 1959: Maintenace building in place and the four antennas shown.

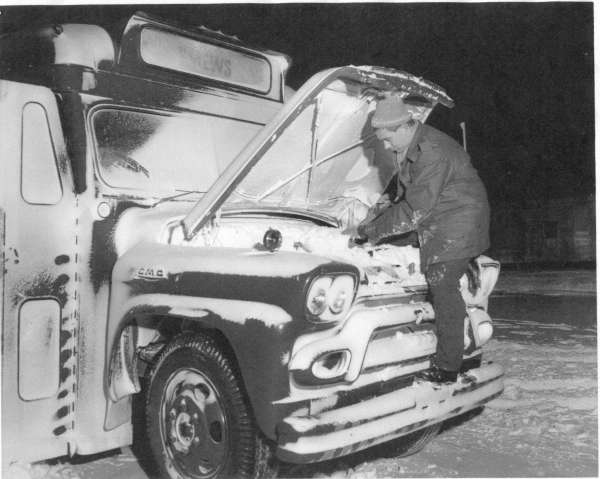

Jan 8, 1960: The maintenance building was the first up with electric heat. We made the mistake of leaving our bus out in a Phase 3 storm. The door was open about 2 inches, and the bus filled up overnight to the ceiling with snow and ice. It was towed, wheels frozen, to a heated area to thaw out for two days. I slept on the building floor and the sides of the building rattled like a train going by outside.

A four-holer outhouse was built out back, overhanging a cliff. We had to wait for the wind to slow down in the right direction to deposit our toilet paper, which with a wrong gust it would hit the ceiling, "splat". In the sever cold you got in and out in a hurry.

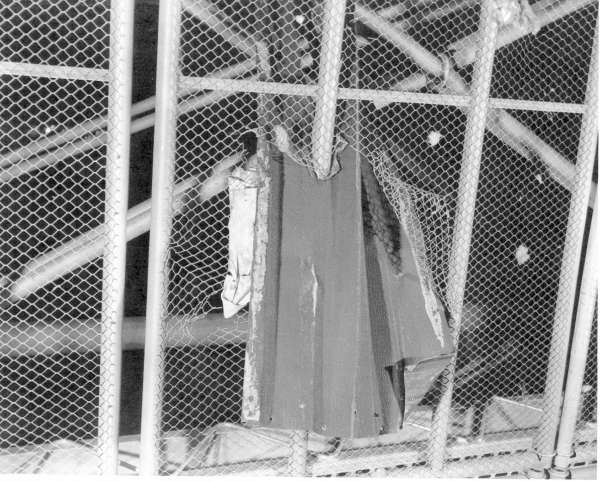

Jan 10, 1960: An example of the force of a phase 3, 120 mph wind off the ice cap. A loose piece of siding of a building cutting through one of the antenna screens.